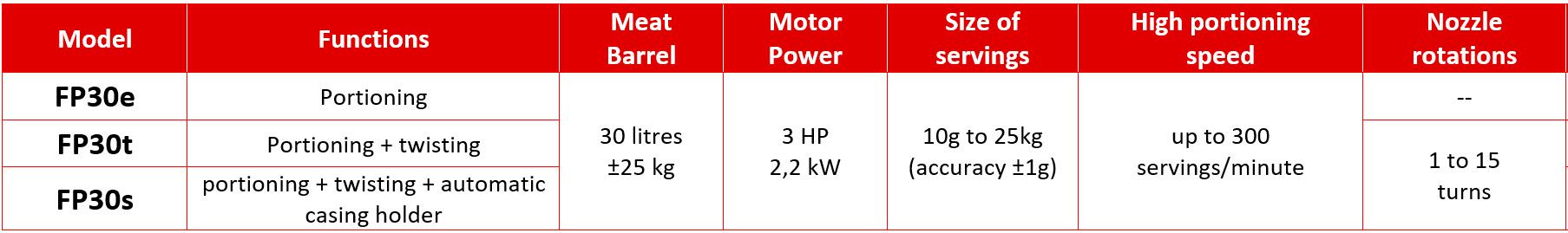

3 POSSIBLE CONFIGURATIONS

Version "e": FILLING AND PORTIONING PROCESS:

- Single or continuous operation, programmable number of portions with automatic stop.

- Filling all kinds of casings, cans, boxes, or other containers.

FP30e

Portioning

Version “t”: AUTOMATIC DIGITAL TWISTER:

- Rotates the nozzle between each portion.

- Number of nozzle turns adjustable from 1 to 15 turns.

FP30t

Portioning+twisting

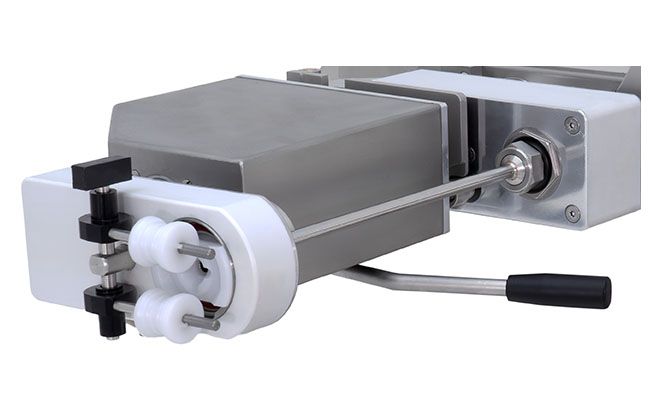

Version “s”: AUTOMATIC DIGITAL TWISTER AND AUTOMATIC MOTORIZED CASING HOLDER:

- The motorized automatic casing holder allows effortless portioning and twisting and ensures precise portions and twist points, with maximum efficiency.

- For synthetic, collagen and natural casings.

FP30s

Portioning+twisting+automatic casing holder

The Talsa FP30 digital automatic food filler with portioning and rotating nozzle has been designed for medium-sized users who need to accurately fill and portion a wide variety of food products with a single machine. The 30-litre barrel capacity allows for the production of medium or small batches without waste and enables rapid product changeover.

Barrel capacity 30 litres

Large 15″ touch screen

Option 4 swivel casters, with brake

ACCESORIES & OPTIONS

Option 4 swivel casters, stainless-steel, whit brake

Standard, long, extra-long stainless-steel nozzles for automatic casing holder, or angled for filling cans, etc.

ACCESSORIES INCLUDED

5 standard nozzles Ø ext 14, 20, 25, 30 and 43 mm.

Hydraulic oil.

Piston extraction key.

AT WORK

- Several assistance systems help the user find the most efficient way to obtain the desired product.

- Intuitive calibration system to produce portions of exact weight based on product density.

- Adjustable rotating nozzle and manual casing retention.

- Clear visual indication of remaining product.

- Number of batches/total and weight counters.

- Portions between 10 g to 25 kg, very precise ±1 g.

- Very fast, can produce up to 300 servings per minute.

- Optional connection to external clipping machine.

ALL STAINLESS STEEL FRAME

- Very robust construction.

- AISI304 stainless-steel frame, exterior and interior, as well as screws and all possible components.

- Smooth surfaces, without angles, with CE radius to facilitate cleaning and compliance with hygiene standards.

- Watertight access panels with double lip seal.

- Closed bottom.

- Adjustable, non-slip stainless-steel feet with anti-vibration rubber support (optional 4 casters).

HYDRAULICS, ELECTRICITY AND ELECTRONICS

- Powerful motor, high hydraulic pressure for the densest or coldest products.

- Frame temperature-controlled, oil cooling system.

- Easy access to the electrical panel.

- Hydraulic/electrical components from quality brands Hydac Germany and Schneider Electric.

- Reliable and accurate internal electronic digital communications using new industry-advanced components, IO-Link brand Balluff Germany.

SOFTWARE AND EXTERNAL CONNECTIONS

- Control panel with large 15” Schneider Electric digital touch screen, all information displayed simultaneously and in large format. Very complete information on controls, alarms, errors, diagnostics, instruction manual.

- Very advanced and practical software with many options, intuitive, easy to use, 4 languages.

- Interactive recipes, which can be stored and executed directly on the screen.

- Software in 4 major languages.

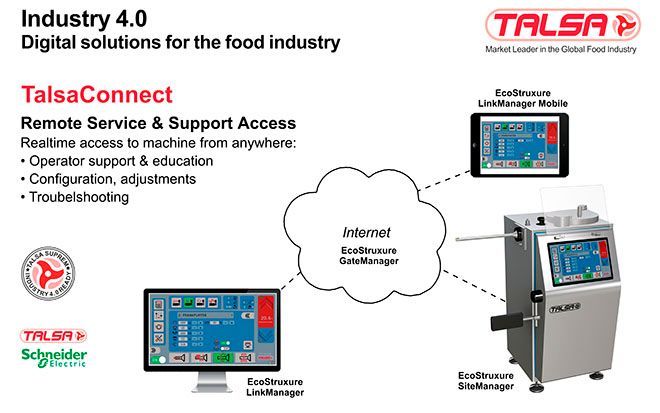

- Industry 4.0 digital solutions for maintenance, process integration and custom solutions.

- Access to services and remote assistance via a secure Internet connection (Ethernet cable or mobile phone).

Automatic casing holder option, fully motorized, latest generation, artificial or natural casing

Large 15″ touch screen, all information displayed simultaneously, very intuitive operation, wizards for adjusting weight/density, creating recipes

Access to services and remote support via secure Internet connection

Distributors

Access

Contact

All Rights Reserved | Talsa